Capabilities

Omega Fabrication

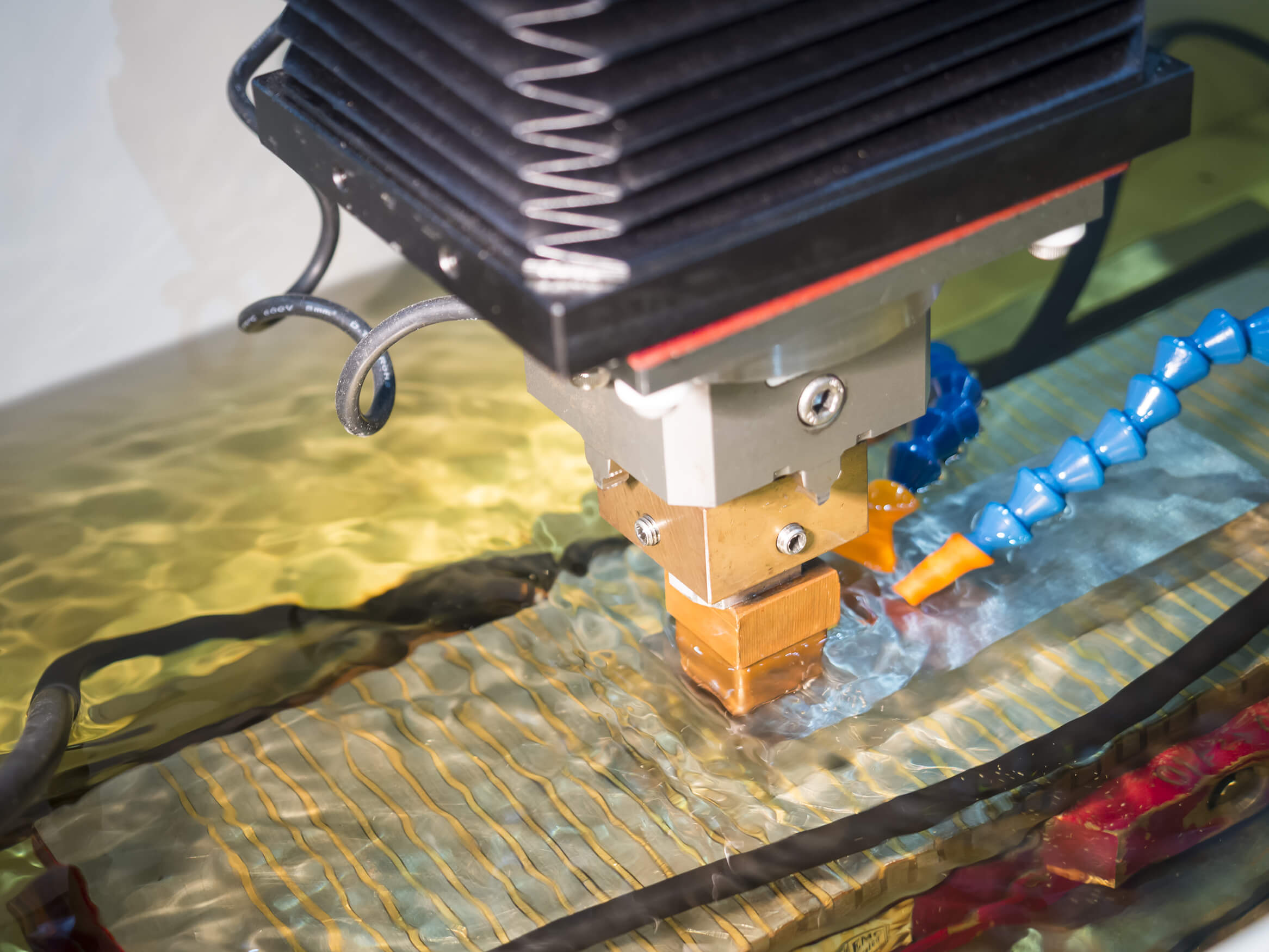

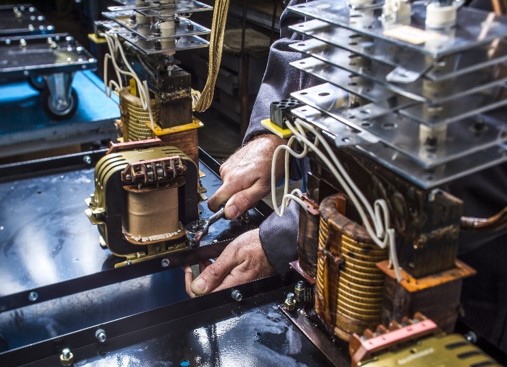

Omega Fabrication provides machining and fabrication services as well as engineering support to ensure high quality specification of all client. We have detailed expertise in the manufacture of high mix low volume precision components.

This competence has particular relevance to the Aerospace, Automation, Semi-Conductor, Solar Energy and Medical devices sector. With high-efficiency machine equipment, ‘lean’ centered manufacturing processes and an incredibly flexible production team, we have a strong emphasis on achieving delivery in full on time.

We have completed manufacture of a wide variety of CNC machined parts, including:

- Precision Part Fabrication

- Tools & Die Fabrication

- Jig & Fixture Fabrication

- Automation Machines Assembly

Integrated System X Traceability

All process is driven by a fully integrated System. This ensures that all ordering, processing and planning related to project is all drawn from the bill of materials, with material traceability and capacity planning well managed throughout.

Materials in Use

Aluminum – Steel – Stainless Steel – Copper, Brass, Bronze – Titanium – Plastic – Rubber – Glass

Industry focus

Automation – Aerospace – Semi-conductor – Medical Device – Solar Energy – General OEM

Equipment Capabilities

Multi-axis Machining – CAD CAM Programming – Reverse Engineering

Machinery Axis

3 Axis – 4 Axis – 5 Axis

Lead Times Available

Quoted on job by job basis

Industry Standards

ISO 9001 – AS 9100